Product Catalog

Deep Groove Ball Bearing

Self Aligning Ball Bearing

Cylindrical Roller Bearing

Spherical Roller Bearing

Angular Contact Ball Bearing

Tapered Roller Bearing

Thrust Ball Bearing

Thrust sphercial roller bearing

Bearing Unit

Linear Bearing

Spherical plain bearing

Stainless Steel Bearing

Taper Bush

Axial Needle Roller and Cage Assemblies

Drawn Cup Needle Roller Bearing Clutch

Machined needle roller bearing

Drawn cup needle roller bearing

Needle Roller and Cage Assemblies

Slide Guide Rails

Ball Screw Support Bearing

Ball Screw Support Bearings

Optical Axis

D 28-62mm

Introduction

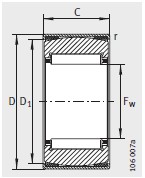

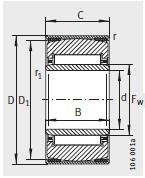

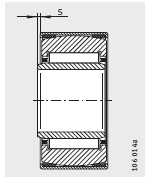

& nbsp; features bearing is a unit composed of stamping outer ring, plastic support ring with spherical inner wall, ferrule with spherical outer surface, needle roller and cage component, and separable inner ring. self aligning needle roller bearings are X-life bearings. These bearings have optimized raceway surfaces. this can ensure higher bearing capacity and longer rated life. the compensation of the alignment can compensate the static alignment of the shaft and the bearing seat up to 3 & deg. bearings cannot be used to support swing motion. the centripetal rotation between the stamped outer ring and the ferrule will produce a moment to separate them. in order to realize the self-aligning rotation, the bearing seat tolerance given in the dimension table must be observed, please refer to the relevant page 754 . needle roller bearings without inner ring have extremely compact radial dimensions. However, they require that the raceway of the shaft be hardened and ground. if the shaft cannot be used as the raceway of rolling bearing, the bearing with inner ring shall be used. the standard inner ring is allowed to have displacement in the axial direction not exceeding the value listed in the dimension table. When large displacement is needed, the standard ferrule can be replaced by wide inner ring IR . inner circle: see page 776 . needle roller bearing without seal. open bearings can be oil lubricated or grease lubricated. limited by plastic support ring, the working temperature range is & ndash; 20 ℃ to + 100 ℃. the cage is a steel plate cage.

in order to ensure that the bearing does not slip during operation, the bearing must bear the minimum load in the radial direction frmin . It is particularly important for high-speed working conditions. If the radial load is not large enough or not, harmful sliding motion will appear on the rolling body and raceway. under continuous operation condition, the minimum radial load must meet the requirements of C R / P 50 . the limit speed in the dimension table n G is only used for oil lubrication. for grease lubrication, the allowable value will be 60% . bearing layout design Tolerance of shaft and bearing seat for the recommended tolerance of shaft with inner ring bearing, see page 150 . for the design of the shaft of the bearing without inner ring, please refer to the raceway part and relevant tables of the bearing without inner ring. recommendation for bearing pedestal

in order to ensure that the bearing does not slip during operation, the bearing must bear the minimum load in the radial direction frmin . It is particularly important for high-speed working conditions. If the radial load is not large enough or not, harmful sliding motion will appear on the rolling body and raceway. under continuous operation condition, the minimum radial load must meet the requirements of C R / P 50 . the limit speed in the dimension table n G is only used for oil lubrication. for grease lubrication, the allowable value will be 60% . bearing layout design Tolerance of shaft and bearing seat for the recommended tolerance of shaft with inner ring bearing, see page 150 . for the design of the shaft of the bearing without inner ring, please refer to the raceway part and relevant tables of the bearing without inner ring. recommendation for bearing pedestal