Product Catalog

Deep Groove Ball Bearing

Self Aligning Ball Bearing

Cylindrical Roller Bearing

Spherical Roller Bearing

Angular Contact Ball Bearing

Tapered Roller Bearing

Thrust Ball Bearing

Thrust sphercial roller bearing

Bearing Unit

Linear Bearing

Spherical plain bearing

Stainless Steel Bearing

Taper Bush

Axial Needle Roller and Cage Assemblies

Drawn Cup Needle Roller Bearing Clutch

Machined needle roller bearing

Drawn cup needle roller bearing

Needle Roller and Cage Assemblies

Slide Guide Rails

Ball Screw Support Bearing

Ball Screw Support Bearings

Optical Axis

d 50-85mm

Introduction

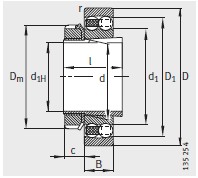

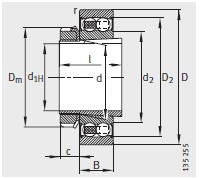

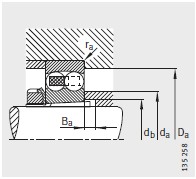

& nbsp; features self aligning ball bearing is a double row non separable bearing. The bearing consists of an outer ring with a spherical raceway, an inner ring with a cylindrical or conical hole, a ball and a cage assembly. Bearings are divided into open and sealed design. radial and axial bearing capacity self aligning ball bearing can bear bidirectional axial load and radial load. with cylindrical or conical hole bearing series 12 , 13 , 22 and 23 have two designs: cylindrical and conical holes. the taper of inner hole of tapered hole bearing is 1 : 12 followed by k . with tightening set self aligning ball bearings with tapered holes also have the types of set sleeve, lock nut and stop washer. In addition to bearings, tightening sleeves must also be ordered. widen the inner ring bearing series 112 has a widened inner ring, and one side of the inner ring has a positioning groove which can be fixed with a positioning pin. this kind of bearing is suitable for simple bearing configuration of conventional shaft. Due to the bearing bore tolerance J7 , the bearing is very easy to install. seal self aligning ball bearing series 12 , 13 , 22 and 23 also have sealed bearings. sealed bearings have contact seals on both sides with the suffix 2RS . lubrication sealed bearings are lubricated with high-quality grease, which is maintenance free. compensation angle is not in the middle under the normal condition of inner ring rotation, the maximum centering angle of the ball bearing relative to its center can reach 4 & deg;; the maximum sealing bearing can reach 1.5 & deg;. Therefore, the relative deflection between the inner ring and the outer ring is allowed, so the misalignment, the deflection of the shaft and the deformation of the bearing seat can be compensated. if it is the case of outer circle rotation or inner circle swing, its heart adjustment ability will be reduced. in this case, please contact us. working temperature the operating temperature range of open bearing with brass cage is - 30 ℃ to + 150 ℃. the maximum working temperature of the bearing with glass fiber reinforced nylon cage is + 120 ℃. Us '>) . cage standard cage for self-aligning ball bearing, see cage and ID code table for details. cage material is glass fiber reinforced nylon 66 with suffix TVH . the suffix of ball guided brass solid cage is m . check the influence of synthetic grease and oil and grease containing EP additives on the chemical stability of nylon materials. under high temperature, aging lubricating oil and additives in oil will reduce the working life of nylon cage. the lubricant change cycle must be followed. cage and ID code

| series | nylon solid cage 1)

|