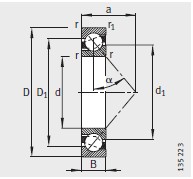

single row angular contact ball bearings are non separable bearings, including: solid inner and outer rings, ball and cage components, and the cage is made of nylon, stamped steel plate or brass.

the raceways of the inner and outer rings offset each other along the axial direction of the bearing. Bearings are divided into open and sealed designs. Their angle adjustment function is very limited.

many types of angular contact ball bearings are X-life series products. Information about these bearings is included in the relevant dimension tables.

X-life series bearings improve raceway geometry and optimize raceway surface.

all of these significantly improve the bearing fatigue limit load. When calculating the corrected bearing rated life, the value of 50% can be obtained. In some applications, this means that a more compact bearing arrangement can be designed.

single row angular contact ball bearing can bear unidirectional axial force and large radial force.

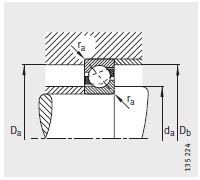

the other bearing installed relative to the adjacent image must be axially adjustable.

axial bearing capacity depends on contact angle. That is to say, the larger the contact angle is, the larger the axial load the bearing can bear. Because of the contact angle of 40 ° the angular contact ball bearing can bear large axial load.

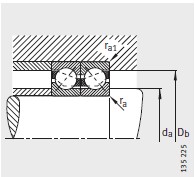

the single row angular contact ball bearing of universal combined design has suffix UA , UL or uo , which can be used for the arrangement of x , o in series or in groups.

these bearings can meet the needs of any installation arrangement. For series arrangement, please pay attention to the description of bearing arrangement design chapter on page 269 .

in the process of ordering bearings, the total number of bearings must be stated, rather than only the number of ordered bearing pairs or bearing groups.

DT) .

suffix 2RS indicates that both sides of the bearing have lip seals. RS contact seal is used to prevent the invasion of dust, pollutants and moisture.

high quality grease is used for lubrication of sealed bearings, which can meet the lubrication requirements in the bearing operation life cycle.

no sealed bearing or only one side sealed bearing has no initial grease. They can be grease lubricated or oil lubricated.

the operating temperature of open angular contact ball bearing is – 30 ℃ to + 150 ℃.

bearings with outer diameter D & gt; 240mm can maintain dimensional stability up to + 200 ℃.

limited by lubricants and sealing materials, the suitable operating temperature range of sealed bearing is from – 30 ℃ to + 110 ℃.