Product Catalog

Deep Groove Ball Bearing

Self Aligning Ball Bearing

Cylindrical Roller Bearing

Spherical Roller Bearing

Angular Contact Ball Bearing

Tapered Roller Bearing

Thrust Ball Bearing

Thrust sphercial roller bearing

Bearing Unit

Linear Bearing

Spherical plain bearing

Stainless Steel Bearing

Taper Bush

Axial Needle Roller and Cage Assemblies

Drawn Cup Needle Roller Bearing Clutch

Machined needle roller bearing

Drawn cup needle roller bearing

Needle Roller and Cage Assemblies

Slide Guide Rails

Ball Screw Support Bearing

Ball Screw Support Bearings

Optical Axis

d 4-460mm

Introduction

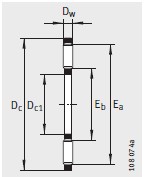

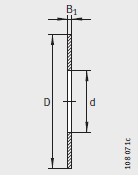

& nbsp; features thrust needle roller and cage components AXK conform to DIN 5405-2 . It is composed of plastic or metal thrust cage and needle roller, with small axial section. cage components can withstand a large amount of unidirectional axial force. The radial load must be borne by other bearings. thrust needle roller and cage components need hardened and ground surfaces as raceways. thrust bearing washer as is a hardened and polished stamping part, suitable for use as shaft ring or seat ring. They conform to DIN 5405-3 and are suitable for use with thrust needle roller and cage assemblies AXK . these washers are suitable for equipment with adjacent parts not hardened but with sufficient rigidity and geometric accuracy. thrust needle roller bearing thrust needle bearing axw includes thrust needle and cage components AXK and thrust bearing washer with centering sleeve. They can be used together with the stamping outer ring needle bearing or machining outer ring needle bearing. the running raceway of needle roller and cage components must be hardened and ground. the operating temperature of needle roller and cage components and needle roller bearing with nylon cage ranges from & ndash; 20 ℃ to + 120 ℃. The suffix of thrust needle cage component with nylon cage is TV . see the following table for the suffix of existing designs. existing design

| suffix | description | Design |

| TV | the cage is made of glass fiber reinforced nylon 66 | standard design |

| RR | corrosion resistant design with < span lang = 'en

|