Product Catalog

Deep Groove Ball Bearing

Self Aligning Ball Bearing

Cylindrical Roller Bearing

Spherical Roller Bearing

Angular Contact Ball Bearing

Tapered Roller Bearing

Thrust Ball Bearing

Thrust sphercial roller bearing

Bearing Unit

Linear Bearing

Spherical plain bearing

Stainless Steel Bearing

Taper Bush

Axial Needle Roller and Cage Assemblies

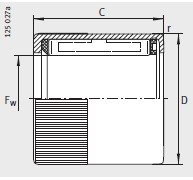

Drawn Cup Needle Roller Bearing Clutch

Machined needle roller bearing

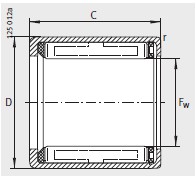

Drawn cup needle roller bearing

Needle Roller and Cage Assemblies

Slide Guide Rails

Ball Screw Support Bearing

Ball Screw Support Bearings

Optical Axis

Index >>

Drawn Cup Needle Roller Bearing Clutch >>

Without bearing,With the knurled or without knurling

D 6.5-42mm

Introduction

& nbsp; features the stamping outer ring needle roller clutch is a one-way clutch, including a series of thin-walled stamping outer rings, nylon cages, springs and needles on the inner wall. They can transmit one-way large torque and are extremely compact in radial direction. There are two kinds of clutches, one with bearing and the other without bearing. the stamping outer ring needle roller clutch has a very high conversion accuracy, which is due to the independent reed of each needle roller belt, so as to ensure the continuous contact between the shaft, needle roller and slope. Because of its light weight and small inertia moment, high conversion frequency is allowed. they also have small beyond friction moment. the stamping outer ring needle roller clutch can be used in various situations, such as positioning clutch, backstop clutch and overrunning clutch. In these applications, the stamping outer ring needle roller clutch has the function of idling or locking. needle roller clutch HF has no bearing and can only transfer torque. stamping outer ring needle roller clutch HF has steel spring, while needle roller clutch HF.. KF uses plastic pressure reed. when using the needle roller clutch without bearing, the axis alignment must be ensured through another rolling bearing, otherwise the needle roller clutch with bearing is needed. the needle roller clutch with knurled outer diameter has a suffix of R , which is applicable to plastic bearing pedestal. the outer surface of the stamping outer ring is processed with knurling wholly or partially along the axial direction. needle roller clutch HFL integrated sliding or rolling bearing, so it can bear torque and radial force. . the stamping outer ring needle roller clutch with knurled outer surface has a suffix of R , and is applicable to plastic bearing pedestal. the outer surface of the stamping outer ring is processed with knurling wholly or partially along the axial direction. the needle roller clutch of stamping outer ring is open at both ends. lithium base grease is used for the needle roller clutch of stamping outer ring. in many applications, the initial filling grease is enough to meet the service life of the bearing. for oil lubricated occasions, needle roller clutch without grease can be provided. These needle clutches are coated with rust inhibitor. For more information on lubrication, see page 799 . limited by grease, the suitable working temperature of the needle roller clutch in the stamping outer ring is & ndash; 10 ℃ to + 70 ℃. see the following table for suffixes of existing designs.

| suffix | ' return html }; function Navigator() { var type = "pc"; if (navigator.userAgent.indexOf('iPad') != -1 || navigator.userAgent.indexOf('iPhone') != -1 || navigator.userAgent.indexOf('Android') != -1) { type = "ipad" } return type }; |