Product Catalog

Deep Groove Ball Bearing

Self Aligning Ball Bearing

Cylindrical Roller Bearing

Spherical Roller Bearing

Angular Contact Ball Bearing

Tapered Roller Bearing

Thrust Ball Bearing

Thrust sphercial roller bearing

Bearing Unit

Linear Bearing

Spherical plain bearing

Stainless Steel Bearing

Taper Bush

Axial Needle Roller and Cage Assemblies

Drawn Cup Needle Roller Bearing Clutch

Machined needle roller bearing

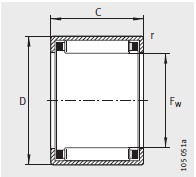

Drawn cup needle roller bearing

Needle Roller and Cage Assemblies

Slide Guide Rails

Ball Screw Support Bearing

Ball Screw Support Bearings

Optical Axis

D 4.6-26mm

Introduction

& nbsp; features open and closed punching outer ring needle bearings are needle bearings with very small radial section size. They are formed into a complete unit by a thin-walled stamping outer ring and a needle roller together with the cage assembly. these designs make the bearing structure particularly compact, easy to install and have high radial bearing capacity. In order to bear the axial force, this kind of bearing is combined with the thrust needle roller bearing axw series, please refer to the dimension table, page 880 . most of these bearings are single row design and have no lubrication holes. The double row design with lubrication holes has a suffix of ZW . for special applications, the open stamping outer ring needle roller bearing also has full needle design. it is required that the raceway on the shaft must be hardened and ground. if the axis cannot be used as a raceway, it needs to be combined with the inner ring series of IR or LR . suitable inner ring: see page 778 . because the axial positioning method such as shoulder block and snap ring is not used, the manufacturing of bearing seat hole is simple and low cost. Therefore, the installation of the bearing is very simple. Open stamping outer ring needle roller bearing can provide two types of needle roller and cage components or full needle roller components. Needle roller and cage assembly bearings are faster than full needle roller bearings. the most number of needles are installed in the full loaded needle punch outer ring needle bearing, so although the size is small, the bearing capacity is very high. However, this kind of bearing is not suitable for high-speed operation. the needle of the full needle bearing is not self-sustaining. To ensure the safety of transportation and installation, the bearing is initially installed with special grease (DIN 51825 & ndash; K1/2K–30)。 however, this grease is not suitable for long-term lubrication. Therefore, it is recommended to relubricate after installation. some pressed outer ring needle roller bearings are closed at one end. They are used to seal the bearing arrangement at the shaft end. The closed end prevents damage caused by the rotating shaft and the ingress of contaminants and moisture into the bearing. according to the size, the closed end has flat or curled edge ( reinforced edge ) . because one end of the bearing is closed, it can bear small axial guiding force. the design of needle bearing without seal for open and closed punching outer ring conforms to DIN 618-1 / ISO 3245 , while the design with seal conforms to DIN 618-2 . under normal operation conditions, the sealing lip can prevent pollution, water splashing and grease leakage. the grease of sealing bearing is lithium-based composite grease ga08 . the maximum working temperature of bearing without seal can reach + 140 ℃. limited by lubricants and sealing materials, the suitable temperature for sealed open and closed punching outer ring needle bearing is & ndash; 30 ℃ to + 100 ℃. the operating temperature range of nylon cage bearing is & ndash; 20 ℃ to + 120 ℃. except for a few, the cage is made of steel plate. the suffix of needle cage component with nylon cage is TV . special design if necessary, special design is also provided. <