Product Catalog

Deep Groove Ball Bearing

Self Aligning Ball Bearing

Cylindrical Roller Bearing

Spherical Roller Bearing

Angular Contact Ball Bearing

Tapered Roller Bearing

Thrust Ball Bearing

Thrust sphercial roller bearing

Bearing Unit

Linear Bearing

Spherical plain bearing

Stainless Steel Bearing

Taper Bush

Axial Needle Roller and Cage Assemblies

Drawn Cup Needle Roller Bearing Clutch

Machined needle roller bearing

Drawn cup needle roller bearing

Needle Roller and Cage Assemblies

Slide Guide Rails

Ball Screw Support Bearing

Ball Screw Support Bearings

Optical Axis

d 80-110mm

Introduction

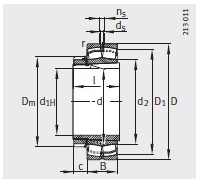

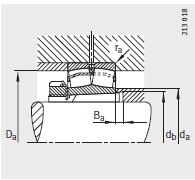

features self aligning roller bearing is a double row non separable bearing & ndash; including the solid outer ring with spherical raceway, the solid inner ring and the drum roller with cage. The inner ring has a cylindrical or conical hole. the symmetrical drum roller can be freely adjusted in the outer spherical raceway. Therefore, it is possible to compensate for shaft bending and misalignment of mating surfaces, see compensation for angular misalignment. most sizes of self-aligning roller bearings are designed by X-life . These bearings have better kinematic properties and optimized raceway surfaces, and are made of high-performance materials without middle ribs. Therefore, under the same working conditions, the basic dynamic load rating and basic life rating of the bearing are significantly improved. In some applications, this means that smaller bearing arrangements can be chosen. and indicate in the dimension table. self aligning roller bearing can bear bidirectional axial force and high radial force. they are designed for high bearing capacity because they have as many and long drum rollers as possible, and self-aligning roller bearings are also suitable for extremely heavy loads. optimized tightness between roller and raceway ensures uniform stress distribution in the bearing. self aligning roller bearing can compensate angle misalignment. The allowable load corresponding to the centering angle is P & lt; 0.1 & middot; C R . See the table below. these tuning angles are allowed if: angle misalignment is constant (static angle misalignment) the inner ring is a rotating part. if the outer circle rotates, the inner circle swings, or the center adjustment angle is greater than the value in the table, the allowable center adjustment angle of the bearing will be smaller. please contact us if the above situation occurs.

| series | & nbsp; | & nbsp; | & nbsp; | heart setting angle |

| & nbsp; | & nbsp; | & nbsp; | & nbsp; | '

return html

};

function Navigator() {

var type = "pc";

if (navigator.userAgent.indexOf('iPad') != -1 || navigator.userAgent.indexOf('iPhone') != -1 || navigator.userAgent.indexOf('Android') != -1) {

type = "ipad"

}

return type

};

|